What does SPOC stand for?

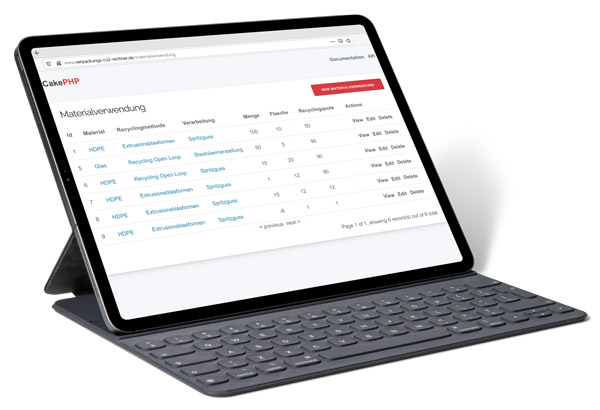

SPOC is the abbreviation for "Sustainable Packaging Online Calculator" and is a tool to quantify the CO2 footprint and energy expenditure for packaging.

It is simple and easy to use and delivers a meaningful and reproducible result in just a few minutes. SPOC thus helps to systematically develop the most sustainable packaging design.

What can SPOC do?

SPOC quantifies the differences between different packaging solutions in terms of CO2 emissions and energy consumption. It is specially designed for food and non-food packaging. The calculations take into account a wide variety of material types, processing processes, transport routes and all common end-of-life variants. This allows packaging to be designed in a more sustainable way.

Who is SPOC for?

SPOC is a neutral, industry- and company-independent tool that provides clear numerical values to all decision-makers developing new packaging solutions. Numerical values that enable packaging engineers, packaging material manufacturers, marketing and sales staff to discuss the sustainability of the developed packaging and optimise it if necessary.

How representative is SPOC?

When calculating the CO2 footprint, SPOC takes into account the recommendations of the ILCD manual as well as the requirements of ISO 14044 and ISO 14067. The calculations are simplified by using standard values for material, process, disposal and transport data. Regular updates ensure that material data and emission factors are up-to-date.

Training with SPOC?

SPOC is easy to use, so the CO2 emissions of packaging are quickly preserved. In order to properly assess the results, it is helpful to understand what is behind the calculations. Therefore, it is recommended to attend a training course. For this purpose, online seminars on the topic of "Quantifying sustainable packaging" are regularly offered.

Sustainable

food packaging

Sustainable

food

packaging

The online packaging calculator SPOC is specially designed for the calculation of food packaging and clearly shows the environmental benefits achieved through recyclability and the use of bio-based materials. For non-food packaging, SPOC can be used to determine the reduction of greenhouse gas emissions when using recycled materials.

The Developers

The online packaging calculator SPOC was developed at the Packaging Chair of the Munich University of Applied Sciences under the direction of Prof. Dr. Dirk Burth and Prof. Dr. Sven Sängerlaub with the aim of supporting a systematic approach to the development of sustainable packaging.

English

English  Deutsch

Deutsch  Italiano

Italiano